Il magazzino del mese

22/03/2013

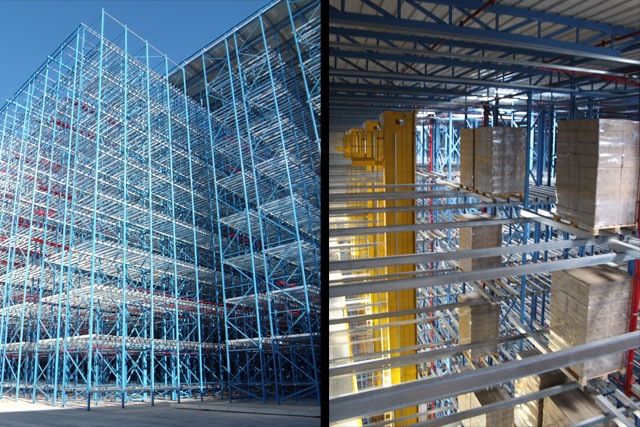

Comes into operation the new automatic warehouse of GROWERMETAL

31/07/2013When a Customer confirms the choice of the Supplier for a new plant, meaning he is a satisfied Customer…

…and the Supplier has fully realized his expectations.

After successfully completing the construction of the automatic warehouse in Riese Pio X, with capacity of about 25.000 pallets, PASTA ZARA (1st Italian exporter of pasta in the world), has once again chosen LYTO’S and STÖCKLIN for his new massive automatic warehouse in Muggia, province of Trieste.

Cantiere del magazzino di Pasta Zara in costruzione

It comes of a self supporting automatic warehouse of large dimensions, that is going to become ever more the most important automatic warehouse for pasta in Italy.

- Over 66.000 pallet locations, stored in double deep, moved by 11 stacker cranes and a sophisticated handling on the front head, whole automation realized by STÖCKLIN (http://www.stoecklin.com/); an area occupied of about 11,000 sqm, a warehouse height of 38 m, a maximum weight of 1,350 kg each unit load.

Also for this realization, Pasta Zara has chosen technical solutions that distinguish since many years Lyto’s proposals: - Design of foundations and metal structures carried out by the expert and experienced team of Lyto’s Engineers;

- “HEA system of foundation” for the fixation of the metal structures directly on the foundation itself, a solution that allow one hand to avoid costs and technical contradictions of drilling and fastening system with chemical anchors, on the other hand to have the slab completely accessible to the working machines, without an high concentration of anchor bars protruding;

- Continuous top hats supporting pallets, fixed over a couple of horizontal beams, with single large frame obtained by welding process realized on Lyto’s production plant;

- Complete realization of the cladding, with related accessories for smoke extraction and control of the internal temperature.

Another major commercial success in a market where the most important General Contractors appreciate and choose since always, solutions and reliability of LYTO’S and STÖCKLIN.

Please read the article on the on-line magazine “Italian Food Materials&Machinery”