PASTA ZARA confirm LYTO’S as supplier for his new warehouse of 65,000 pallets

29/05/2013

A jewel realized together with System Logistics in Italy

20/10/2013Successfully completed the test, it started loading of the new automatic warehouse realized by LYTO’S and LCS, for the Company based in Calco (LC).

Has arrived to the end the realization of an automatic warehouse that has seen for the first time work together LYTO’S and LCS Logica Consulting & Solution (www.lcssrl.it),

Company located in Usmate (Milan) that since 1989 deals with automatic handling and storage systems, integrating mechanical standard components produced by their exclusive partner KardexMlog.

Suppliers have been chosen directly from the Owners of Growermetal after careful and accurate assessments that have affected not only all technical aspects, but also those aspects related to the reliability and the financial soundness of the Companies.

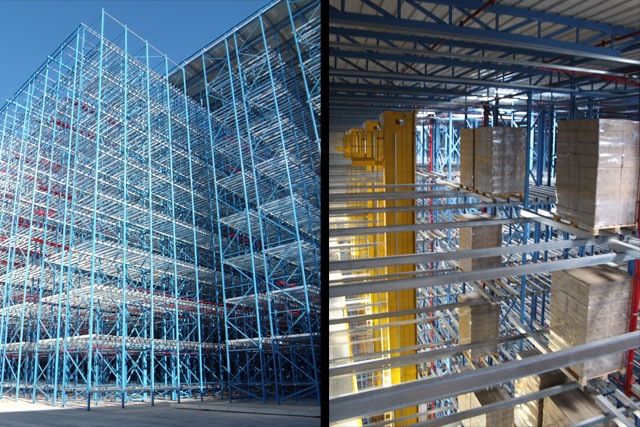

Particularly LYTO’S has dealt not only the realization of the steel bearing structures of the warehouse and its forepart, but also the structural design of the foundations (particularly challenging for the relevant size of the loads and for the solution of land consolidation adopted) and the complete cladding of the building, realized according to the Customer’s choice about colours and its alternation.

Below the main data of the project realized:

- storage capacity: nr. 5,688 unit load (base dimensions 1200×800 mm) or nr, 10,986 unit load (base dimensions 600×800 mm), weight 1000 kg or 600 kg;

- buildings dimensions: warehouse 18x50x h 20 m, fore part 29x6x h 8 m (including in the scope of suplly of Lyto’s);

- structural tipology: self supporting structure, with transverse elements in each compartment to allow the storage of both unit load with dimensions 1200×800 mm and 600×800 mm;

- handling system: nr. 4 stacker cranes by KardexMlog-LCS fed by conveyors located in the front of the warehouse and by 4 LGV vehicles for the service on the warehouse, and various others areas, as picking, packaging and shipping;

- performances: nr. 140 combined cycles/hour (each cycle is composed by one input and one output). Number of hour cycles increase in case of only inputs or outputs to or from the warehouse.

Great satisfaction for the work done by Suppliers, great appreciation for the seriousness and correctness of a Client who has personally followed the completion of the project, since the design choices to the finishing details.

Result is an automatic warehouse “jewel” that makes modern and efficient the logistics of GROWERMETAL.